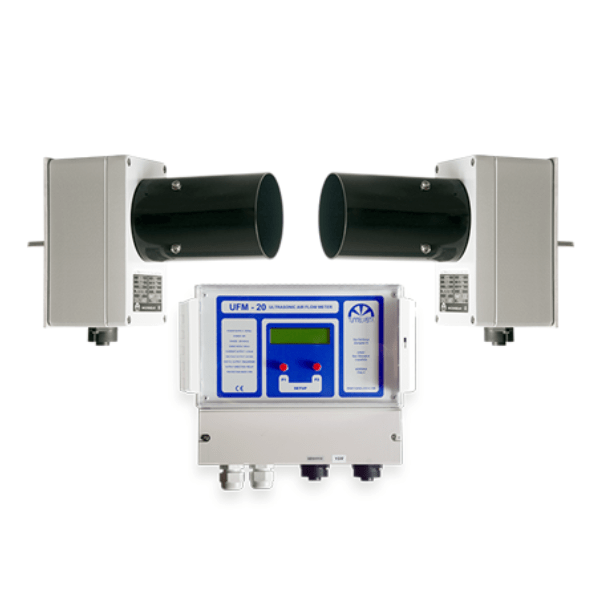

Ultrasonic Anemometer UFM20

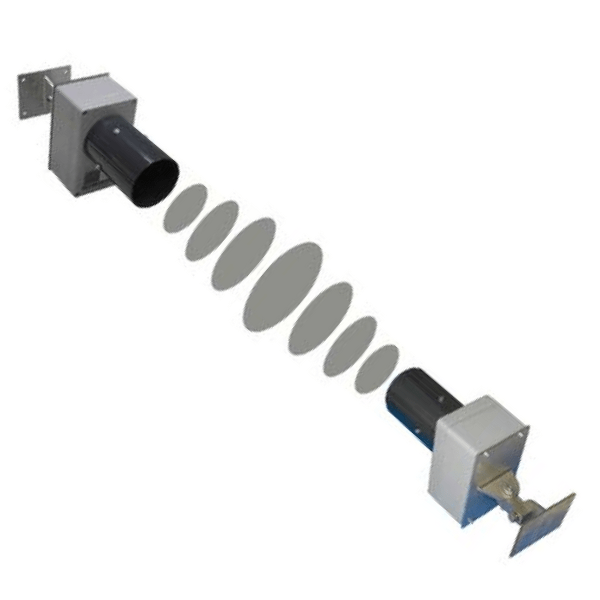

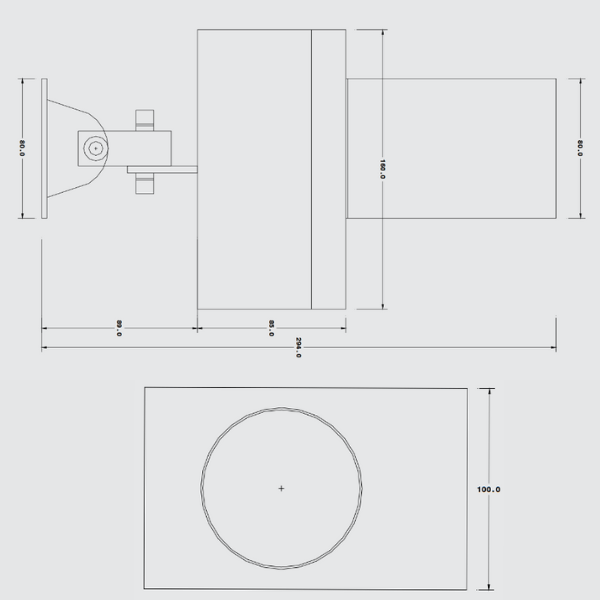

The UFM20 ultrasonic air flow meter consists of two powerful transducers strategically placed on opposite sides of the tunnel; These specialized devices accurately measure the average air velocity and direction in the tunnel section; The angular arrangement, typically at 45 degrees over a 20-25 meter span, ensures a representative measurement of airflow in that specific area;

This innovative anemometer, developed by TUNNELVISTA, is not only capable of monitoring air speed and direction in road tunnels, but also stands out for its reliability and ease of installation; In addition, its versatility allows its application in a variety of situations, such as adjusting the natural air flow of the tunnel by means of ventilation control, especially in cases of opacity or gas levels above a safe limit;

The UFM20 works by means of two ultrasonic elements (transducers) that emit and receive ultrasonic signals; These transducers are strategically placed on opposite sides of the tunnel, forming a fixed angle with the direction of air flow; The principle of operation is based on the transit time of the ultrasonic sound between the two transducers; The difference in the transit times of the ultrasonic signals back and forth between transducers A and B provides crucial information about the air velocity and direction in the tunnel;

The data collected by the system, i.e. air speed and direction, are essential for identifying hazardous conditions; These data are processed by a control panel that integrates a microprocessor and a processing unit; The information obtained is used to inform the tunnel ventilation control system, enabling it to take appropriate measures to purify the air and optimize energy consumption efficiently;

In short, the UFM20 not only ensures accurate and reliable measurements over time, but also plays a key role in the safety and operational efficiency of tunnels, enabling a proactive response to adverse conditions and contributing significantly to environmental care and energy savings;

Features

- No moving mechanical parts

- No need for spare parts;

- Ultrasonic “barrier” technology

- No contact measurement

- Maintenance-free: operational control once a year

- LCD display for visible measurement and configuration;

- Analog and digital outputs;

- Quick and easy installation

- Long life

- Power supply : 220 Vac

- Power consumption: 120 mA

- Measuring principle: difference between ultrasonic transit times

- Measuring range:- 20 / +20 m/s

- Resolution: 0.1 m/s

- Precisión: +/- 2% en el rango de medición completo

- Ultrasonic path: 0-20 m

- Analog voltage output: 0-5 V

- Analog current output: 4-20 mA

- Salida de relé para dirección de aire digital.

- Digital output for PC interface: RS232/RS485

- High temperature alarm output (+60°C) – optional

- Ambient working temperature: -20 +55 °C

- Distancia máxima entre los transductores y la centralita: 200 m.

- Protection rating: IP65

- Built according to standards: DIN EN ISO 9001- 2008 and EC directives 2004/108 and 2006/95

Detection of air flow speed and direction in the following environments:

- Road and railway tunnels

- Tunnel escape routes and detours;

- Ventilation pipes

- Exhaust gas extraction pipes;

- Industrial installations;